Custom CNC Machining Services Since 2013

Your Go-To Source for Custom CNC Machining Components, from prototypes to mass production parts. Get an instant quote and DFM feedback for your projects today.

- Trusted by 10+ public companies

- Tolerance as tight as ±0.01 mm

- ISO 9001:2015 compliant

- Quick delivery as 7 days

CAPABILITIES

Our CNC Machining Services

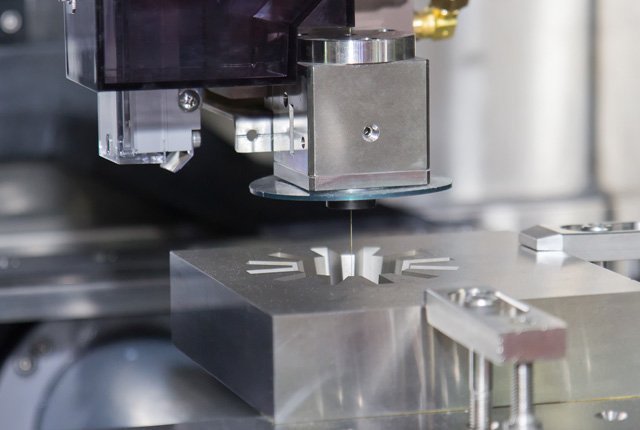

Discover a comprehensive solution tailored to your CNC machining needs. Our services include advanced 3, 4, and 5-axis CNC milling, precise CNC turning, Swiss turning, along with specialized precision grinding, EDM, laser cutting, and more, all designed to bring your projects to life with exceptional accuracy and efficiency.

Gallery

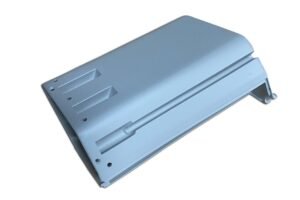

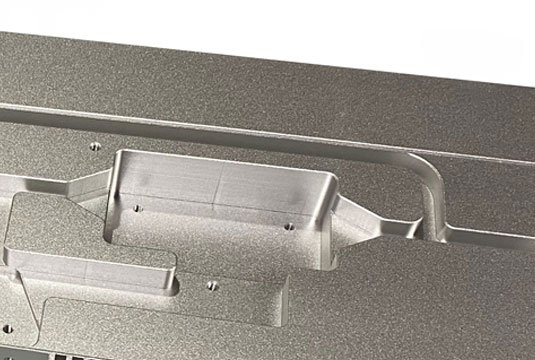

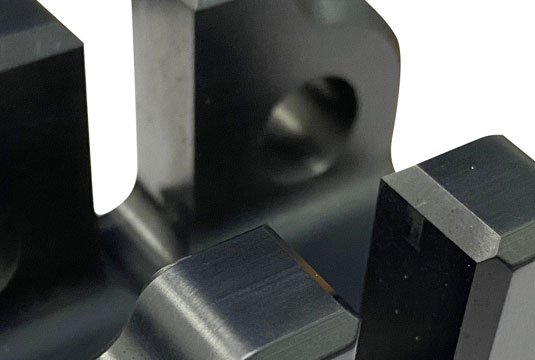

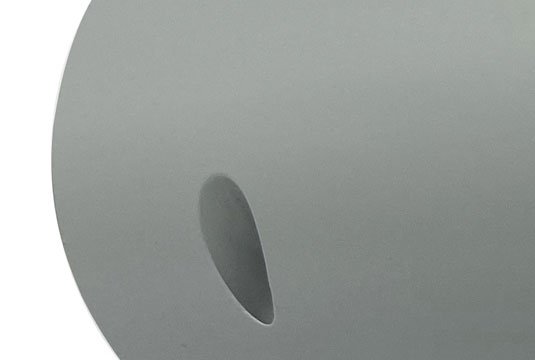

CNC Machined Parts Gallery

Explore the range of custom CNC machined prototypes and end-use parts we’ve expertly machined.

Materials

CNC Machining Materials

Empower your manufacturing with a diverse selection of materials for CNC machining, offering a plethora of options from rapid prototyping to full-scale production of custom complex parts. We streamline your decision-making with instant quotes for over 40 metals and plastics, enabling you to easily compare prices and choose the best machining materials for your specific needs.

Our aluminum boasts outstanding machinability, welding, and electroplating capabilities, coupled with impressive corrosion resistance. What sets it apart is its post-machining reliability, with minimal risk of deformation or defects, and effortless polishing and coloring.

Aluminum reigns as a widely embraced metal across diverse industries. Its applications span the automotive, defense, aerospace, transportation, construction, packaging, electronics, consumer goods sectors, and beyond.

We provide an expansive selection of Aluminum types tailored to your specific needs. This range includes the versatile Aluminum 6061-T6 and 7075-T6, along with specialized options like Aluminum 6082, 5083, 6063, 5052, 2024, 7050, MIC6, 2017, A380, and 2014

Stainless steel, an eco-friendly alloy, it blends iron, carbon, and 11-18% chromium, ensuring robustness, high corrosion resistance, and immunity to rust even at elevated temperatures.

Our CNC machining services are specifically tailored to leverage these strengths of stainless steel. Catering to sectors like energy, medical technology, agriculture, industrial automation, machinery and robotics.

We offer a comprehensive selection of stainless steel alloys. This includes SS303, known for its easy machining; Stainless Steel 304/304L and 316/316L, renowned for their balance of corrosion resistance and strength; Stainless Steel 17-4, prized for its exceptional hardness; and Stainless Steel 416, favored for its enhanced machinability.

Alloy steels offer an exceptional solution. Their composition, enriched with various alloying elements alongside carbon, significantly enhances their inherent qualities. This results in a material that not only exhibits high strength and toughness but also boasts remarkable resistance to fatigue. The improved hardness and wear resistance of these alloy steels make them ideally suited for applications where durability and longevity are paramount, ensuring your projects benefit from materials that are as resilient as they are robust.

We provide a range of specialized alloy steels. This selection includes AISI 1215, known for its excellent machinability; AISI 4140, a versatile alloy with a great balance of strength, toughness, and wear resistance; AISI 4340, recognized for its high strength and toughness; AISI 8620, valued for its strength and low cost; and AISI 4130, a reliable choice for its strength and resilience.

Tool steels stand as an exemplary choice. Characterized by their exceptionally high hardness and stiffness, these metal alloys excel in abrasion resistance. This unique combination of properties makes them ideal for crafting a wide range of industrial tools, ensuring that they not only perform under demanding conditions but also maintain their integrity and effectiveness over time. With tool steels, you're equipped with materials that are specifically engineered to withstand the rigors of industrial usage, guaranteeing durability and efficiency in your manufacturing processes.

We offer a curated selection of tool steels. This includes A2 Tool Steel, renowned for its excellent balance of hardness and toughness; D2 Tool Steel, known for its high abrasion resistance and hardness; O1 Tool Steel, favored for its ease of machining and good wear resistance; S7 Tool Steel, valued for its high impact resistance; and M2 Tool Steel, distinguished by its high heat resistance and superior red hardness.

Renowns for its excellent thermal and electrical conductivity, copper is extensively utilized in applications such as busbars, wire connectors, and a myriad of other electrical components.

We offer a range of copper grades, each with distinct characteristics. These include:

- C10100 - Also known as Oxygen-Free Electronic (OFE) copper, notable for its high purity and exceptional electrical conductivity.

- C11000 - Commonly referred to as Electrolytic-Tough-Pitch (ETP) copper, it combines excellent conductivity with good formability.

- C12200 - A Phosphorus-Deoxidized copper, known for its excellent corrosion resistance and weldability, ideal for plumbing and heating applications.

- C14500 - Tellurium copper, distinguished by its high machinability and conductivity, making it suitable for electrical components and connectors.

- C17200 - Beryllium copper, recognized for its highest strength and hardness among all copper alloys, used in demanding applications like aerospace components.

Renowned for its superb machinability and exceptional electrical conductivity, brass is the go-to material for applications demanding minimal friction. Its distinctive golden appearance not only adds aesthetic value but also signifies quality and durability. Ideal for enhancing the performance and reliability of your mechanical designs and electronic devices.

Copper 260, with its enhanced strength and corrosion resistance, is perfect for components where durability is key. Meanwhile, Copper 360 stands out for its exceptional machinability, ensuring smooth and efficient production processes.

This metal stands out with its outstanding strength-to-weight ratio, making it a top choice for the aerospace, automotive, and medical industries. Its low thermal expansion ensures stability under varying temperatures, while the high corrosion resistance offers longevity even in demanding environments. Notably, its sterilizability and biocompatibility make it ideal for medical applications, ensuring safety and durability.

Titanium Grade 2, known for its excellent corrosion resistance and ductility, is ideal for applications requiring robustness and longevity, particularly in corrosive environments. It's the perfect choice for quality-sensitive industries where durability is a priority.

On the other hand, Titanium Grade 5, also known as Ti 6Al-4V, is renowned for its higher strength and ability to withstand extreme temperatures. This grade is the go-to option for applications demanding the utmost in strength and thermal resistance, making it a preferred material in the aerospace, medical, and automotive sectors.

ABS, a widely used engineering plastic, stands out for its exceptional mechanical properties, including high strength, stiffness, and toughness. It also offers impressive chemical resistance, abrasion resistance, and impact durability.

For industries like automotive and electronics, precision matters. GPM delivers high-quality ABS components tailored to your needs, perfect for applications such as engine housings, electronic equipment mounts, decorative panels, and beyond. Trust in precision where it counts most.

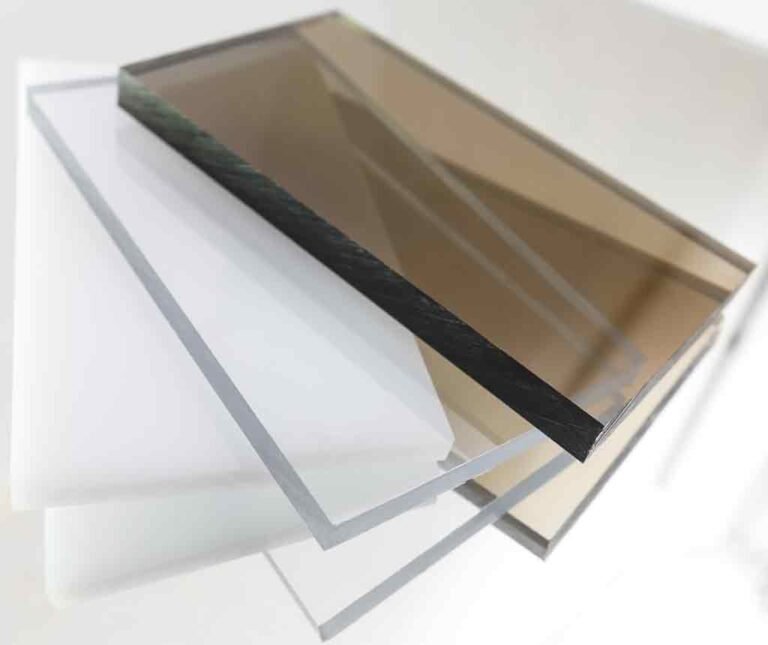

Acrylic, or polymethylmethacrylate (PMMA), is a favored material for CNC machining, known for its exceptional transparency, ease of machining, dimensional stability, and resistance to abrasion and chemicals. This makes it an excellent choice for producing parts that demand high precision, superior surface quality, and specific transparency requirements.

GPM's precision machining services ensure your acrylic components meet stringent quality standards. Ideal for sectors like automotive and advertising, our parts enhance applications such as display panels, lampshades, billboards, and retail displays. Delivering clarity and precision where visual impact and durability matter.

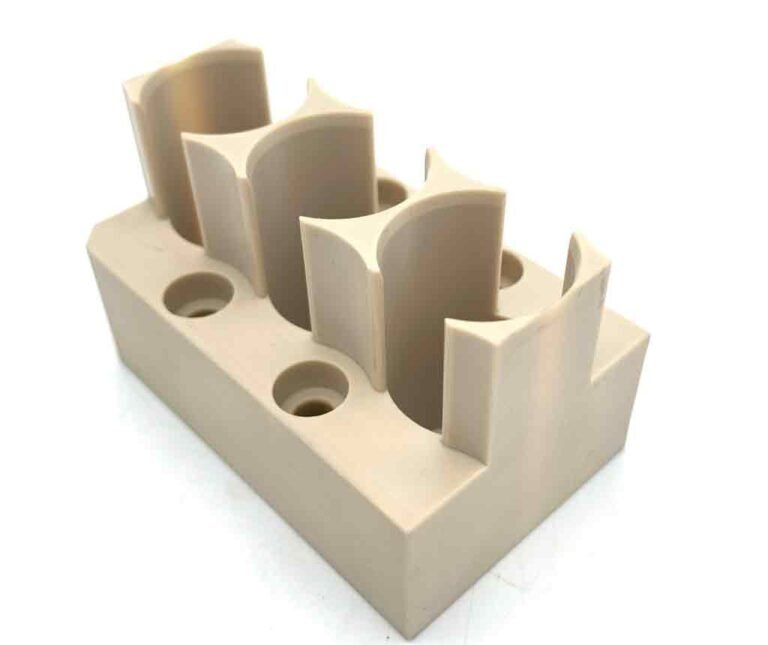

Delrin, or polyoxymethylene (POM), is a high-performance engineering plastic renowned for its high rigidity, outstanding wear resistance, low coefficient of friction, and impressive chemical and dimensional stability.

GPM’s precision machining services ensure that your Delrin components are manufactured to the highest quality standards. Serving critical sectors like automotive and electronics, these parts are perfectly suited for gears, regulators, connectors, bearings, gaskets, and more. Depend on precision and reliability for applications where performance is key.

Nylon is a versatile synthetic polymer that combines high tensile strength, excellent stiffness, low friction, chemical resistance, and heat resistance. These characteristics make it a top choice for high-performance applications.

GPM’s precision machining services deliver top-quality nylon components for demanding industries like automotive and electronics. Ideal for parts such as blades, suspension brackets, plug housings, connector bases, bearings, gears, and washers, these components are crafted to excel in rigorous conditions.

Additionally, nylon’s low moisture absorption and dimensional stability ensure consistent performance even in humid environments, offering reliability where it matters most.

PC, or polycarbonate, is a high-performance engineering plastic celebrated for its impressive strength, exceptional transparency, heat resistance, chemical resistance, and reliable electrical insulation properties.

GPM's precision machining services provide high-quality polycarbonate components tailored for industries like electronics and medical. From electronic housings and bulkheads to headlamp lenses and medical containers, each part is crafted to meet rigorous performance and quality standards. Count on precision where durability and clarity are essential.

PEEK, or polyether ether ketone, stands out as a premium engineering plastic known for its exceptional high-temperature resistance, superior chemical resistance, robust mechanical properties, and minimal water absorption.

GPM’s precision machining services ensure that your PEEK components are manufactured with uncompromising quality. Perfect for the chemical and aerospace industries, our parts are ideal for applications such as engine components, manufacturing housings, piping, connectors, impellers, and more. When performance under extreme conditions is critical, precision and reliability come standard.

PET, or polyethylene terephthalate, is a widely used thermoplastic polymer, valued for its high tensile strength, excellent abrasion resistance, reliable heat resistance, superior electrical insulation, and outstanding fatigue resistance.

GPM's precision machining services deliver high-quality PET components tailored for industries like packaging and electronics. From screen protectors and electronic housings to medical packaging, our parts are crafted with meticulous precision to meet demanding industry standards. Choose quality that ensures durability and consistent performance.

Surface Finishes

CNC Machining Surface Finishes

Explore a range of custom surface finishes designed to meet both your aesthetic requirements and performance standards. Elevate your components with precision finishing that adds value and functionality.

Anodize

Anodizing is an electrochemical process that significantly improves the corrosion resistance, durability, and appearance of metals, especially aluminum.

Sand Blast

Achieve a clean, uniform, and matte finish with our bead blasting services, expertly removing rust, paint, scale, and other contaminants from a wide range of surfaces.

Black Oxide

Black Oxide finishing delivers both aesthetics and protection, offering a matte black look while reducing corrosion and wear for long-lasting metal durability.

DLC Coating

Reduce surface resistance and enhance durability, extending the lifespan of tools, mechanical components, and precision parts in demanding applications.

Nickel Plating

Ensures uniform thickness and a smooth finish, providing an appealing look and consistent protection. Materials gain enhanced resistance to friction and abrasion.

Electropolish

Electropolishing boosts metal corrosion resistance by eliminating impurities and creating a clean, passive surface for superior performance and longevity.

Powder Coating

We provide an extensive selection of paint spraying services in a variety of colors, tailored to meet your specific design preferences and functional requirements.

Heat Treatment

Enhance material properties through heat treatment, improving hardness, strength, toughness, and stress relief to ensure better performance and long-lasting durability.

Equipment

CNC Machining Equipment List

At GPM, we utilize a comprehensive array of advanced CNC machining equipment to deliver precision parts with consistent quality. Here’s an overview of our key equipment.

| Main Production Equipment | Processing Stroke(mm) | Quantity | Unit | Accuracy(mm) |

|---|---|---|---|---|

| V8 high speed machining center | 800*500*550 | 3 | Set | ±0.005 |

| V8 high speed machining center + four-axis | 800*500*550 | 2 | Set | ±0.005 |

| V8 high speed machining center + five-axis | 800*500*550 | 5 | Set | ±0.005 |

| T6 high speed machining center + five-axis | 600*400*300 | 5 | Set | ±0.005 |

| T6 high speed machining center | 600*400*300 | 10 | Set | ±0.005 |

| 1060 machining center | 1000*600*600 | 2 | Set | ±0.005 |

| Turning and milling machining center | 300*500*200 | 5 | Set | ±0.005 |

| Fine hole discharge motor | 650*450*300 | 1 | Set | ±0.05 |

| EDM Machine | 450*350*200 | 1 | Set | ±0.01 |

| Wire Cutting Machine (medium) | 450*550*400 | 3 | Set | ±0.005 |

| Wire Cutting Machine (medium) | 400*550*250 | 2 | Set | ±0.005 |

| Manual milling machine | 900*405*350 | 2 | Set | ±0.02 |

| Hand grinding machine | 150*400*400 | 1 | Set | ±0.005 |

| Semi-automatic grinding machine | 150*400*400 | 2 | Set | ±0.005 |

| Large water grinding machine | 400*800*400 | 1 | Set | ±0.005 |

| Tapping Machine | 3 | Set |

| Main Inspection Equipment | Processing Stroke(mm) | Quantity | Unit | Accuracy(mm) |

|---|---|---|---|---|

| CMM | 1 | Set | ±0.003 | |

| VMM (Vision measuring machine) | 300x200mm | 1 | Set | 4+L/50um |

| Height Gauge | 0-700mm | 2 | Set | 3+L/150um |

| Rockwell Hardness Tester | 1 | Set | ||

| Mitutoyo Digital Caliper | 20 | Set | ±0.01 | |

| Mitutoyo Digital Micrometer | 20 | Set | ±0.001 | |

| And more… |

Ordering Process

It is Easy & Safe Working With Us

Leave the complexities to us—gain the precision and reliability you need to lead confidently.

Our expert engineering team, with two decades of hands-on experience, will conduct a comprehensive manufacturability assessment of your project. We meticulously evaluate design specifications, material choices, and process requirements to ensure optimal production efficiency. Once the assessment is complete, we provide a detailed and transparent quote, giving you a clear understanding of the production scope, costs, and timelines, so you can proceed with confidence.

Our engineering team breaks down your design drawings into detailed process plans and meticulously cross-checks 2D and 3D files to identify and resolve any design issues before production begins. By addressing potential problems upfront, we ensure a smooth and efficient manufacturing process. You stay focused on innovation, while we handle the complexities, delivering solutions that pave the way for successful production.

Our facility is equipped with a full range of machining processes, including turning, milling, grinding, wire cutting, and EDM. This allows us to handle complex projects efficiently, ensuring your orders are completed quickly and meet strict quality standards. By managing all processes in-house, we optimize production speed and maintain precise control over every detail.

Our rigorous quality inspection process includes IQPC, QE, OQC, and more, utilizing advanced instruments such as CMM, height gauges, projectors, plug gauges, and pin gauges for high-precision dimensional checks. Additionally, our quality team performs a thorough visual inspection to eliminate any imperfections like scratches or burrs. Every component undergoes strict inspection at each production stage to guarantee that the final product aligns perfectly with your technical specifications and quality standards.

Each part is carefully packaged with tailored solutions to prevent damage during transit. Packages are clearly labeled for easy identification without the need to open them. After secure packaging, parts are placed in sturdy 5-layer corrugated boxes or wooden crates, cushioned with pearl cotton for added protection. A detailed packing list is attached to the outer box for your convenience.

Our extensive experience in global logistics allows us to partner with top international transport and courier companies to ensure you receive your products quickly and cost-effectively. During the quoting process, we provide a tailored shipping assessment, offering multiple options for your convenience. For small quantities, we utilize international express services like DHL, FedEx, or UPS, or opt for air transport. For larger, heavier shipments, we recommend cost-efficient methods such as sea freight or truck delivery, ensuring optimal solutions for your needs.

Get An Accurate Quote For Your Next Projects!

Our pricing engineers are ready to evaluate your project and provide a professional quote.

Why Us

GPM is a team 100% Focus on overseas market with 20+ years experience.

Choose a partner who prioritizes reliability and quality, minimizing risks and ensuring seamless, high-precision production for your critical projects.

- Tight Tolerance at +/-0.005mm

- Quick CNC parts As Fast As 3 Day

- Mass production shipped in 10-14 Days

- 50+ Machining Materials

- Zero risk corporation

- ISO 9001:2015 certified

Common Questions

Most Popular Questions

GPM offers a full range of machining services, including CNC Milling, 3-Axis and 5-Axis CNC Machining, CNC Turning, Swiss CNC Turning, EDM Machining, and Precision Grinding. Our capabilities are tailored to deliver exceptional quality and precision for complex parts and assemblies across various industries.

For tighter tolerance needs, GPM offers precision machining with ±0.05 mm (0.002 in.) or even ±0.01 mm (0.0005 in.) on reamed holes, depending on the complexity of your design and material used. Our standard tolerance for both prototype and production parts is ±0.10 mm (0.005 in.), suitable for most applications. Additionally, feature locations on the same side of the part can hold ±0.05 mm (0.002 in.).

When your design calls for exceptional accuracy, make sure to specify these requirements during the quoting process. With the right part geometry and material, GPM is capable of delivering even higher precision upon request.

GPM provides a wide variety of surface treatments to improve both the appearance and functionality of machined parts. Options include anodizing, black oxide, bead blasting, electropolishing, plating, powder coating, and polishing. Each treatment is selected to meet your specific performance and aesthetic requirements.

While GPM specializes in prototypes and low-volume production, we are fully equipped to manage large-scale manufacturing runs. Whether your order is for a single unit, 100 pieces, or exceeds 1,000 units, we ensure each part is delivered with a production-quality finish.

At GPM, there is no minimum order quantity. Whether you require small batch production or large-scale manufacturing, we are equipped to handle your needs efficiently. Our commitment is to deliver high-quality service regardless of order size, ensuring your specifications are met precisely. Serving your unique requirements is central to our mission.

At GPM, quotes are typically provided within 48 hours. Our quoting process is handled manually, ensuring greater accuracy compared to automated systems. This approach allows us to deliver precise and tailored estimates based on your specific project requirements.

Standard lead times at GPM range from 10-15 days. If you have urgent requirements, we offer expedited services, which can reduce lead time to as fast as 1-2 business days, depending on the complexity and material availability. Our flexible production scheduling is designed to meet your critical timelines without compromising quality.

GPM has extensive experience serving a variety of innovative industries, including automation, medical equipment, semiconductors, and electronics manufacturing. Our expertise allows us to deliver precision-engineered solutions tailored to the unique requirements of these advanced sectors.

At GPM, we use advanced inspection equipment, including CMM (Coordinate Measuring Machine), VMM (Vision Measuring Machine), and height gauges, to ensure all parts meet your specifications. Every component is thoroughly inspected before shipment, and we provide detailed inspection reports for complete transparency and quality assurance.

Partnering with GPM is risk-free. If any quality issue arises due to our error, we offer either rework or repair services to ensure your satisfaction. Our goal is to build long-term partnerships, not one-time transactions. You can trust us to stand by our commitment to quality and reliability.

Our packaging meets international shipping standards to ensure the safe delivery of your parts. For fragile, pressure-sensitive components or heavy items, we use custom plywood crates for added protection. Every part is securely packed to prevent damage from impacts or collisions during transit, ensuring your order arrives in perfect condition.

Yes, GPM provides reliable international shipping options. We commonly use your preferred courier accounts, such as DHL, FedEx, UPS, or TNT, for hassle-free delivery. Alternatively, we can prepay the shipping costs on your behalf if needed, ensuring a seamless and flexible logistics experience.

GPM provides competitive bulk discounts for high-volume orders. Our pricing structure is flexible and designed to accommodate varying quantities, ensuring cost-effective solutions for your large-scale production needs.

Our payment term is flexible. GPM offers Net 30 payment terms for established clients with a proven credit history. This flexible payment option is designed to support your cash flow and foster long-term, trustworthy partnerships.

Get a free quote

Contact Us for a Free Quote Today!

Submit your designs for a free quotation in 24 hours. Rest assured, your intellectual property will be safeguarded with the utmost care. We uphold strict confidentiality protocols, treating your IP with the same level of security as our own.